Surface roughness tester is a crucial tool in various industries to ensure the quality and performance of products. This article will discuss why surface roughness tester is so important in manufacturing and engineering processes.

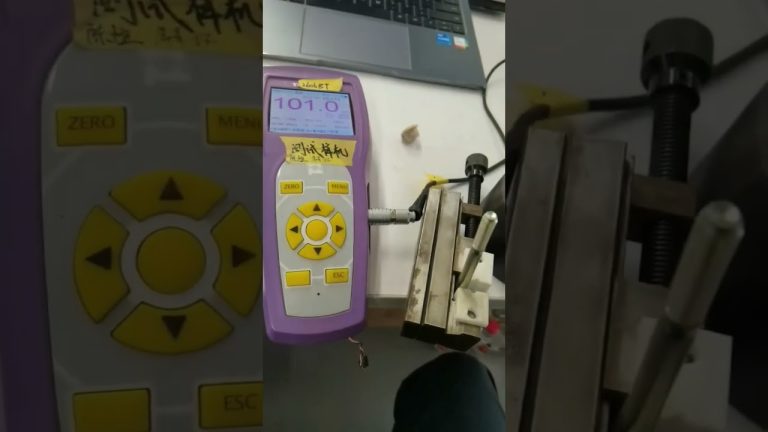

Surface roughness tester is used to measure the roughness of a surface by quantifying the deviations in the surface profile. It provides valuable information about the texture, finish, and quality of a surface, which is essential for determining the functionality and durability of a product. In manufacturing processes, surface roughness tester helps to ensure that the surface meets the required specifications and standards, leading to higher quality products and reduced defects.

One of the key reasons why surface roughness tester is so important is its impact on the performance of mechanical components. The roughness of a surface can affect the friction, wear, and fatigue of a component, which can ultimately lead to failures and malfunctions. By using a surface roughness tester, manufacturers can identify and address surface irregularities early in the production process, preventing costly issues down the line.

Surface roughness tester is also crucial for quality control and inspection purposes. By accurately measuring the surface roughness of a product, manufacturers can ensure that it meets the desired standards and specifications. This is especially important in industries such as automotive, aerospace, and medical, where precision and quality are paramount.

Surface roughness tester plays a vital role in ensuring the quality, performance, and reliability of products in various industries. By accurately measuring and analyzing surface roughness, manufacturers can improve the overall quality of their products, reduce defects, and enhance customer satisfaction. Investing in a surface roughness tester is essential for any company that values quality and precision in their manufacturing processes.