A phased array flaw detector is an advanced non-destructive testing (NDT) tool used to detect and evaluate flaws or defects in materials or structures. It utilizes the principles of phased array ultrasonic testing (PAUT) to provide accurate and detailed inspection results.

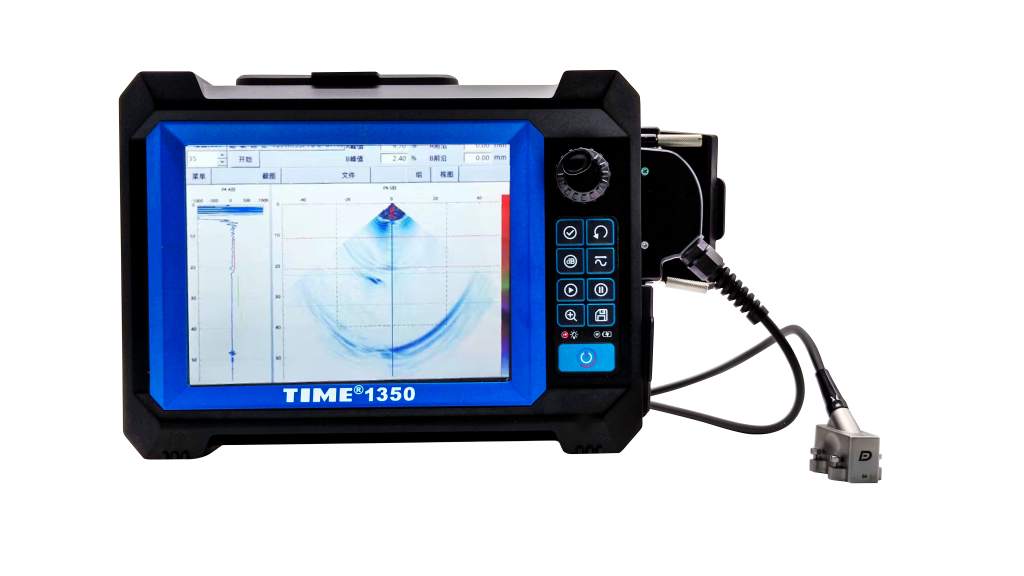

Phased array flaw detectors consist of several small ultrasonic transducers that can emit and receive ultrasonic waves. These transducers are arranged in a linear or matrix array and can be electronically controlled to emit ultrasonic waves at different angles and focal points. This allows for the creation of a focused and steerable beam of ultrasonic energy.

The phased array technique is based on the principle of constructive and destructive interference of ultrasonic waves. By controlling the timing and intensity of the ultrasonic waves emitted by each transducer, the phased array flaw detector can produce a wide range of beam angles and focal points. This enables the inspection of various materials and geometries with high precision and flexibility.

One of the main advantages of a phased array flaw detector is its ability to perform rapid and accurate inspections. The electronic control of the ultrasonic beam allows for fast scanning of large areas, reducing inspection time significantly compared to traditional NDT methods. Additionally, the ability to focus the ultrasonic beam enables better detection and characterization of flaws, improving the reliability and accuracy of inspection results.

Another key feature of phased array flaw detectors is their ability to generate real-time imaging. The received ultrasonic signals are processed and displayed as a visual representation of the inspected object, known as a B-scan. This allows inspectors to identify and locate flaws with ease, facilitating decision-making for repair or maintenance actions.

Phased array flaw detectors are widely used in various industries, including aerospace, automotive, oil and gas, and construction. They are particularly valuable for inspecting complex geometries, such as welds, pipelines, and turbine blades. The ability to perform inspections without damaging the tested material makes phased array flaw detectors a preferred choice for quality control and safety assessment.

A phased array flaw detector is a powerful NDT tool that utilizes the principles of phased array ultrasonic testing to detect and evaluate flaws or defects in materials or structures. Its ability to perform rapid inspections, generate real-time imaging, and provide accurate results makes it an indispensable asset in the field of non-destructive testing.