When it comes to metallographic testing, most friends may not have heard much of it, after all, it is basically difficult to see in our macroscopic world. Its appearance is mainly for studying metallographic microstructures, determining the spatial morphology of three-dimensional structures through measurement and calculation. This technology not only greatly improves the accuracy of metallographic testing, but also improves its speed and greatly shortens working time.

In a sense, metallographic testing is the study and analysis of the internal structure of metals based on people’s subjective consciousness, applying physical metallurgy theory to practical operation processes, testing the composition of metals and alloys, and analyzing their properties.

Before conducting metallographic testing, the following two preparations must be made:

One is to conduct extensive testing and research on the composition, structure, and properties of materials, and complete the understanding of materials through theoretical data.

The second is to compare and study the regularity of materials based on their characteristics, in order to understand the common characteristics and special properties between materials, which has extremely important guiding significance for metallographic inspection.

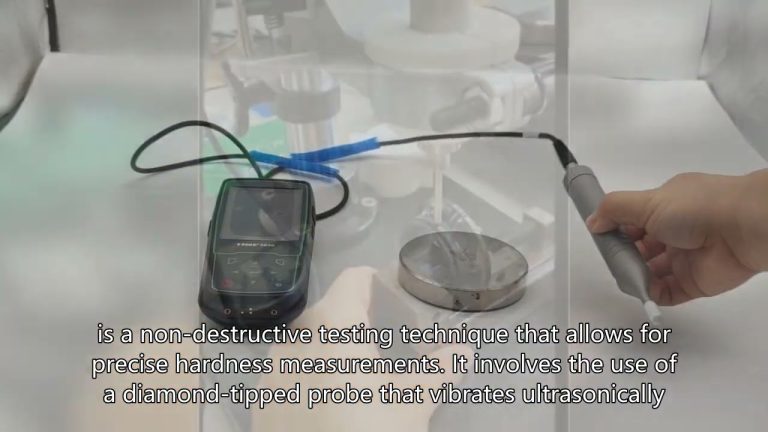

However, although we have already explained the principle of metallographic testing to everyone, for those who do not understand, they may still not understand it. After all, this is indeed a relatively unfamiliar word, and it is generally rare to see it in our daily lives. To put it more vividly, metallographic testing is like treating metal materials, or treating people in hospitals with ultrasound, CT, and so on. It only detects the morphology and distribution of various tissues, phases, and textures inside metal materials. Because the same material has different performance requirements when used in different places, the morphology and structure of its organization are also different. Metallographic testing is the process of determining whether a workpiece meets the performance requirements based on its metallographic structure and morphology.

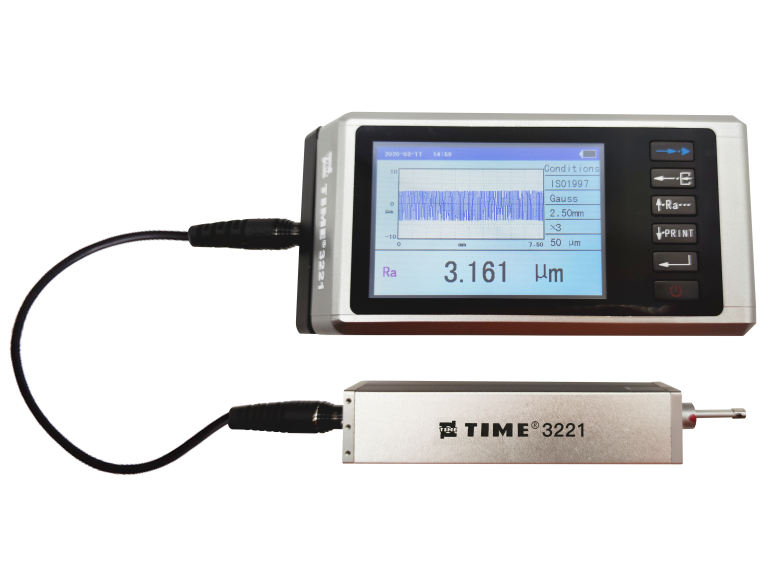

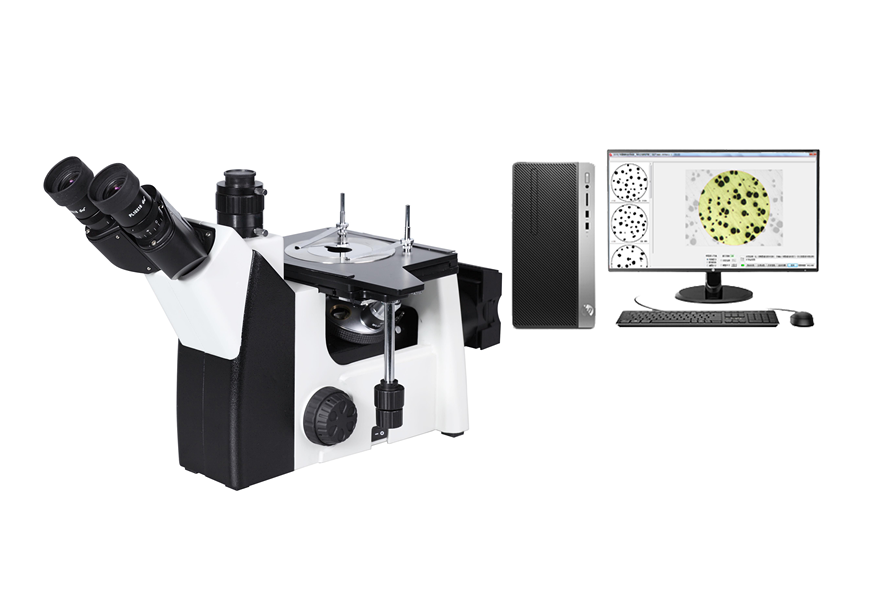

Speaking of which, I believe everyone is quite clear about what metallographic testing specifically does. For users engaged in laboratory work, they should often use some equipment and consumables for metallographic testing. TIME Group specializes in the research and development, production, and sales of metallographic equipment and materials, and has independently developed a series of metallographic equipment and materials. If you have any needs in this regard, you can contact us at any time, We look forward to working with you!