In the field of material testing, the ability to accurately measure hardness is crucial for ensuring the quality and performance of various components. TIME5630 Ultrasonic Hardness Tester has emerged as a reliable solution for hardness measurement, particularly in batch testing scenarios. Now we introduce TIME5630 Ultrasonic Hardness Tester in batch testing, highlighting its advantages, methodology, and case studies.

Overview of the TIME5630 Ultrasonic Hardness Tester

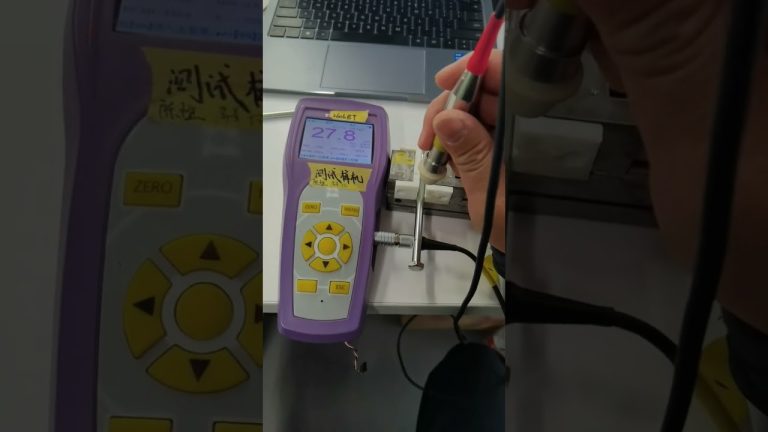

The TIME5630 Ultrasonic Hardness Tester utilizes ultrasonic wave technology to measure the hardness of materials non-destructively. This portable device is designed for quick and accurate measurements, making it ideal for batch testing in manufacturing environments. The device operates based on the principle that the speed of ultrasonic waves traveling through a material is influenced by its hardness. By measuring this speed, the tester can provide precise hardness values.

Key Features

– Non-destructive Testing: The TIME5630 allows for hardness testing without damaging the sample, making it suitable for quality control in production lines.

– Portability: Its lightweight design enables easy transport, allowing for on-site testing and reducing the need for material handling.

– Wide Range of Materials: The tester can evaluate a variety of materials, including metals, plastics, and composites, making it versatile for different industries.

– User-friendly Interface: With a clear display and intuitive controls, users can quickly learn to operate the device, facilitating efficient batch testing.

Methodology for Batch Testing

Batch testing with the TIME5630 Ultrasonic Hardness Tester involves several systematic steps to ensure accurate and consistent results:

1. Sample Preparation: Ensure that the surfaces of the samples are clean and smooth to facilitate accurate readings.

2. Calibration: Before testing, calibrate the device using standard hardness materials to ensure measurement accuracy.

3. Testing Procedure:

– Place the ultrasonic probe on the sample’s surface.

– Initiate the measurement process, allowing the device to send ultrasonic waves through the material.

– Record the hardness value displayed on the screen.

4. Data Collection: Conduct multiple measurements on each sample and record the results for statistical analysis.

5. Analysis and Reporting: Compile the data to assess the hardness consistency across the batch and generate reports for quality assurance.

Case Study 1: Automotive Component Manufacturing

An automotive parts manufacturer implemented the TIME5630 Ultrasonic Hardness Tester for batch testing of steel components. The company faced challenges with inconsistent hardness levels, which affected the durability of their products. By using the TIME5630, they were able to conduct rapid hardness assessments during the production process. The non-destructive nature of the tester allowed for immediate feedback, enabling adjustments in the manufacturing parameters. As a result, the manufacturer reported a 30% reduction in rejected parts due to hardness inconsistencies.

Case Study 2: Aerospace Material Quality Control

An aerospace company required stringent quality control measures for aluminum alloys used in aircraft components. The TIME5630 was adopted for batch testing to ensure compliance with industry standards. The ability to test multiple samples quickly allowed the quality control team to maintain production schedules without compromising on quality. The ultrasonic hardness tester provided reliable data that facilitated informed decisions regarding material acceptance, leading to enhanced safety and performance in their aircraft designs.

TIME5630 Ultrasonic Hardness Tester has proven to be an invaluable tool for batch testing across various industries. Its non-destructive testing capabilities, portability, and user-friendly design make it an ideal choice for manufacturers seeking to ensure material quality and consistency. By adopting this advanced testing technology, companies can enhance their production processes, reduce waste, and improve overall product reliability. As industries continue to evolve, the TIME5630 Ultrasonic Hardness Tester stands out as a key asset in the pursuit of excellence in material testing.