BEIJING TIME VISION AI INSTRUMENT LTD.

https://timetech-ndt.com/

Email: timehardnesstester@gmail.com

WhatsApp: 008615201625204

——————————————————————————————————–

UCI testing, also known as the Ultrasonic Contact Impedance method, is a non-destructive testing technique that allows for precise hardness measurements. It involves the use of a diamond-tipped probe that vibrates ultrasonically, creating a small indentation on the material’s surface. The indentation depth is then analyzed to determine the material’s hardness.

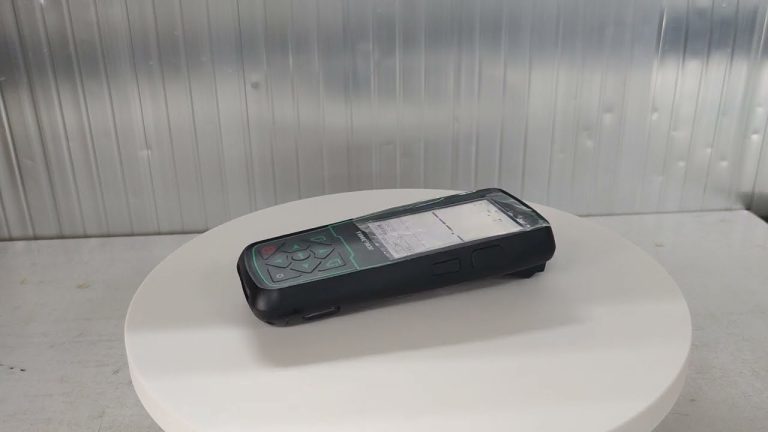

The ultrasonic hardness tester consists of a handheld PDA and a CUI measurement probe. The two are connected by a cable. The diamond indenter at the front of the hardness tester is in contact with the test piece. Under uniform contact pressure, the resonant frequency of the probe changes with the hardness. Change, by measuring the change in frequency, the purpose of measuring hardness is achieved.

There are many methods that can be used for hardness testing, such as Brinell, Rockwell, Vickers, Leeb, ultrasonic, etc. Among them, Brinell and Rockwell hardness cause greater damage to the surface of the object to be tested, while Vickers is more expensive, and neither can test large workpieces; Leeb hardness tester is an indirect measurement of hardness, and the test deviations of Brinell, Rockwell, and Vickers are large. . With the technological development of microprocessors, ultrasonic non-destructive testing methods have gained industry recognition. Ultrasonic thickness gauges and flaw detectors have been widely used, and ultrasonic hardness meters have also become popular abroad.