The principle of ultrasonic thickness measurement.

Ultrasonic thickness detection methods include resonance method, interference method, pulse echo method and so on. Now the working principle of pulse echo method is mainly used to detect thickness.

The ultrasonic probe is in contact with the surface of the measured object. The main controller controls the transmitting circuit, so that the ultrasonic waves emitted by the probe reach the bottom surface of the measured object and reflect back. The pulse signal is received by the probe, amplified by the amplifier and added to the vertical deflection plate of the oscilloscope. The mark generator outputs the time mark pulse signal, which is applied to the vertical deflection plate at the same time. The scanning voltage is applied to the horizontal deflection plate.

Therefore, the time interval t between transmitting and receiving ultrasonic waves can be directly read on the oscilloscope. The thickness h of the measured object is:

h=ct/2

where c——the propagation speed of ultrasonic wave.

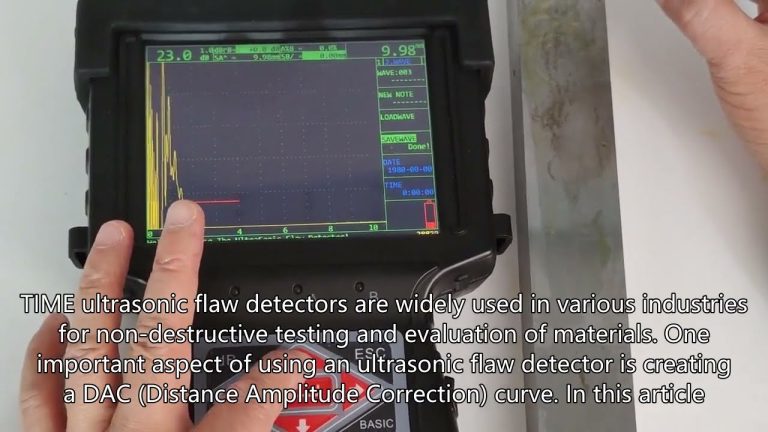

In China we mainly uses integrated circuits to make digital ultrasonic thickness gauges, which are small enough to be held in the hand, weigh less than 1kg, and have an accuracy of 0.01mm, for example: TIME2110 ultrasonic thickness gauge and TIME2130 ultrasonic thickness gauge of TIME Group.

Why use couplant for ultrasonic thickness gauge measurement?

Ultrasonic waves will rapidly attenuate when they encounter air. In order to discharge the air between the ultrasonic probe and the workpiece, ultrasonic coupling agent is used to remove it. Usually, general engine oil or other non-corrosive liquids can be used to measure the smooth surface of the workpiece in the factory, and thicker butter can be used for the rough surface. After the measurement, the surface of the probe and the surface of the standard block must be wiped off with coupling agent.

Why do you need a high temperature couplant for measuring high temperature pipelines?

Generally, when the couplant contacts a high-temperature object, it will evaporate or dry out instantly, so that it is difficult for the ultrasonic wave to reach the workpiece to be tested. The high-temperature couplant means that its object properties will not change under a certain high-temperature state, so that the high-temperature object can be measured. .