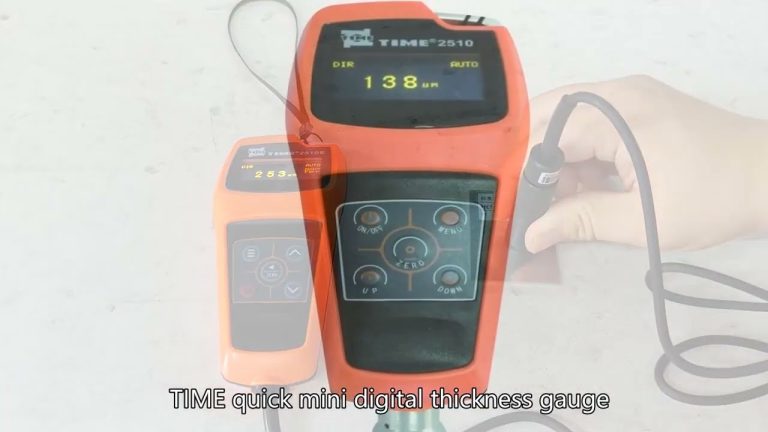

TIME®2511 is the most economical digital coating thickness gauge that uses magnetic induction method to measure non-magnetic coatings (e.g. paint, plastic, porcelain enamel, copper, zinc, aluminum, chrome etc.) on ferrous substrates (e.g. iron, nickel etc.).

This paint thickness meter is ideal for painted surface testing, car paint inspection, coated material testing, and quality control applications. TT210 adopts both magnetic induction (F) and eddy current (N) measuring methods.

Features

●TIME2511 adopts magnetic induction (F) measuring method.

●TT210 adopts two measuring methods: magnetic induction (F) and eddy current (N).

●Single point measurement mode for TIME2511; two measuring modes for TT210: Continuous / Single

●Easy zero point calibration

●TIME2511: 3 adjustable resolutions for different applications

●High speed data collection

●Automatically switch off

●Easy conversion between mm and inch

| Model | TIME2511 | TT210 | ||||

| Probe types | F | F | N | |||

| Measuring methods | magnetic induction | magnetic induction | eddy current | |||

| Measuring range | 0 to 1250 μm | 0 to 1250 μm | 0~1250 μmo~40μm (for chromeplate on copper) | |||

| Minimum resolution | 1μm | 5μm | 10μm | |||

| Tolerance | Zero point calibration | ±(3%H+1)μm | ± (3%H+1.5)μm | ± (3%H+10)μm | ±(3%H+1)μm | ± (3%H+1.5)μm |

| Two point calibration | H means the thickness of tested piece | ±[(1~3)%H+1]μm | ±[(1~3)%H+1.5]μm | |||

| Min. curvature radius (mm) | Convexity 1.5 | Convexity 1.5 | Convexity 3 | |||

| Min. testing area diameter (mm) | Ø7 | Ø7 | Ø5 | |||

| Critical thickness of substrate (mm) | 0.5 | 0.5 | 0.3 | |||

| Power supply | Battery AAA (2pcs) | |||||

| Working temperature | 0~40°C | |||||

| Dimensions (mm) | 110×50×23 | |||||

| Weight (g) | 100 | |||||

| Standard Delivery | |

| Main unit | 1 |

| Substrate | 1 |

| AAA 1.5V battery | 2 |

| Waist pack for main unit | 1 |

| TIME certificate | 1 |

| Warranty card | 1 |

| Instruction manual | 1 |