Roughness measuring machines, also known as roughness testers, are essential tools used in various industries to evaluate the surface texture of a material. These machines provide accurate measurements of surface roughness, which is crucial for quality control and ensuring the proper functioning of mechanical components.

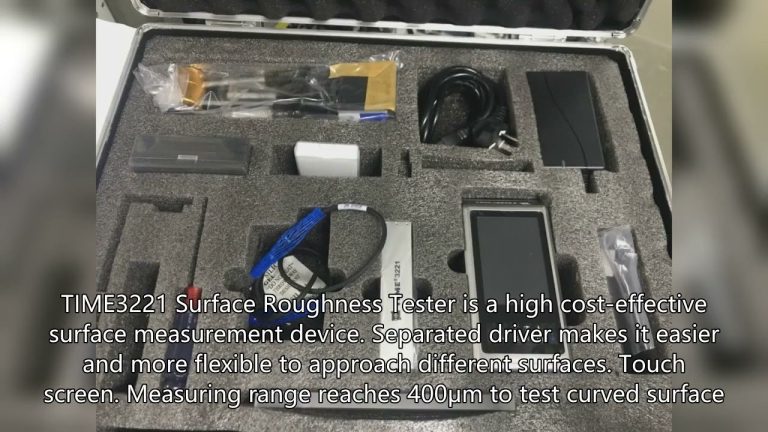

There are different types of roughness measuring machines available, each with its own set of features and capabilities. The most common type is the portable roughness tester, which is convenient for on-site measurements and inspections. These handheld devices are easy to use and provide quick results, making them ideal for field applications.

Another popular type of roughness measuring machine is the desktop roughness tester, which is more advanced and offers higher precision measurements. These machines are typically used in laboratories and manufacturing facilities where precise surface roughness measurements are required. They often come with additional features such as automatic data analysis and reporting capabilities.

Roughness measuring machines work by using a stylus or probe to scan the surface of a material and record the variations in height. The data collected is then used to calculate parameters such as Ra (average roughness), Rz (peak-to-valley roughness), and Rq (root mean square roughness), which provide valuable information about the surface quality.

Roughness measuring machines play a vital role in ensuring the quality and performance of materials and components in various industries. Whether it’s for quality control, research, or production purposes, these machines are indispensable tools for evaluating surface roughness and maintaining high standards of precision and accuracy.