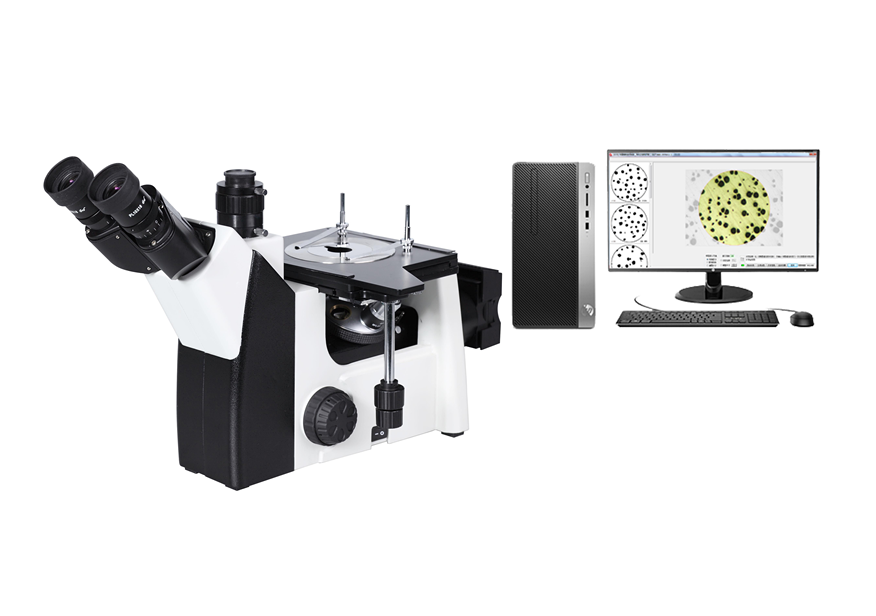

Computerized Metallurgical Microscope TIME-2000W

TIME-2000W is a computerized trinocular inverted metallurgical microscope, used to identify and analyze the structure and components of various metals and alloy materials. It is widely used in factories or laboratories for the identification of casting quality, raw material inspection or metallographic analysis after processing, as well as the research of some surface phenomena such as surface spraying. It is the ideal equipment for metallographic analysis of steel, non-ferrous metal materials, castings, coatings, lithofacies analysis, and microscopic analysis of compounds and ceramics in the industrial field.

Focusing Mechanism

It adopts the coaxial focusing adjustment mechanism for coarse and fine adjustment, which can be adjusted on both the left and right sides, with high precision of fine adjustment, simple and convenient manual adjustment, and users can easily obtain clear and comfortable images. The coarse adjustment stroke is 38mm, and the fine adjustment accuracy is 0.002mm.

Stage

It adopts a large-size stage of 180×155mm and is set in the right-hand position, which conforms to users’ operating habits. It is convenient to switch the operation of focusing adjustment and platform movement, providing users with a more efficient working environment.

Illumination

Koehler illumination system with variable aperture diaphragm and center adjustable field diaphragm adopts adaptive wide voltage 100V-240V, 5W high brightness, long life LED lighting.

|

Optical system |

Finity color corrected optical system |

|

|

Viewing head |

45°inclined, trinocular, interpupillary distance adjustable between: 54-75mm, binocular : trinocular=80%:20% |

|

|

Eyepiece |

High eyepoint wide field plan eyepiece PL10X/18mm |

|

|

High eyepoint wide field plan eyepiece PL10X/18mm with optional micrometer |

Optional | |

|

High eyepoint wide field eyepiece WF15X/13mm with optional micrometer |

Optional | |

|

High eyepoint wide field eyepiece WF20X/10mm with optional micrometer |

Optional | |

|

Objectives (LWD plan achromatic metallurgical objective)

|

LMPL5X /0.125 WD15.5mm |

|

|

LMPL10X/0.25 WD8.7mm |

|

|

|

LMPL20X/0.40 WD8.8mm |

|

|

|

LMPL50X/0.60 WD5.1mm |

|

|

|

LMPL100X/0.80 WD2.00mm |

Optional | |

|

Nosepiece |

Four-position nosepiece |

|

|

Five-position nosepiece |

Optional | |

|

Focusing adjustment |

Low position coaxial coarse and fine adjustment system. Coarse adjustment stroke: 38 mm; fine adjustment accuracy:0.02m |

|

|

Stage |

three-ply mechanical stage,area 180mmX155mm,right hand low position control, Moving range:75mm×40mm |

|

|

Stage plate |

Metal stage plate, center hole dia.φ12mm |

|

|

Illumination system |

Reflection Koehler illumination With variable aperture diaphragm and center adjustable field diaphragm, wide-range voltage 100V-240V, single 5W warm color LED with continuous intensity |

|

|

Koehler illumination With variable aperture diaphragm and center adjustable field diaphragm, wide-range voltage 100V-240V, 6V/30W halogen bulb with continuous intensity |

Optional | |

|

Polarizing kit |

Polarizer insert, fixed analyzer insert, 360°rotating analyzer insert |

Optional |

|

Color filters |

Yellow, green, blue, matte color filters |

|

|

Metallographic Analysis Software |

FMIA2020 Metallographic analysis software; Sony chip 5 million camera device, 0.5X adapter lens interface, high-precision micrometer |

|

|

Computer |

HP business PC |

Optional |