Ultrasonic thickness gauges have become essential tools in various industries, including manufacturing, construction, and maintenance, due to their ability to accurately measure the thickness of materials without causing damage. Among the many brands available, TIME ultrasonic thickness gauges stand out for their precision, reliability, and user-friendly features. In this article, we will explore the key features and advantages of TIME ultrasonic thickness gauges.

Key Features of TIME Ultrasonic Thickness Gauges

1. High Accuracy and Resolution**: TIME ultrasonic thickness gauges are designed to provide highly accurate measurements, often with an accuracy of ±0.1 mm or better. This level of precision is crucial for applications where material integrity is critical.

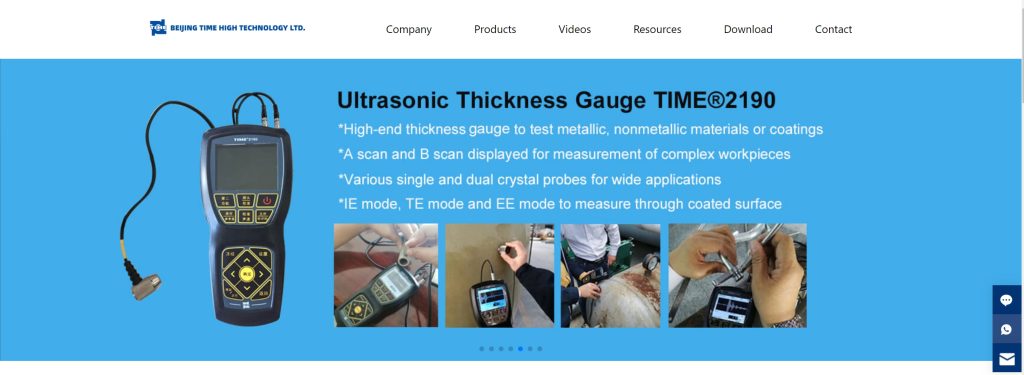

2. Wide Measurement Range**: These gauges can measure a variety of materials, including metals, plastics, and ceramics, with thicknesses ranging from just a few millimeters to several centimeters. This versatility makes them suitable for diverse applications across different industries.

3. Digital Display**: TIME gauges come equipped with a clear digital display that provides easy-to-read measurements. Many models also include backlit screens, allowing for visibility in low-light conditions.

4. Calibration and Data Storage**: TIME ultrasonic thickness gauges often feature built-in calibration options to ensure ongoing accuracy. Additionally, many models offer data storage capabilities, enabling users to save measurements for later analysis and reporting.

5. User-Friendly Interface**: The intuitive design of TIME gauges ensures that they can be easily operated by both experienced professionals and novices. Simple buttons and clear menus make navigation straightforward.

6. Durability and Portability**: TIME ultrasonic thickness gauges are built to withstand harsh working environments. Their rugged construction ensures longevity, while lightweight designs make them easy to transport.

7. Multiple Measurement Modes**: Many TIME models offer various measurement modes, such as single-point measurement, continuous measurement, and averaging modes, which enhance flexibility and accuracy in different scenarios.

8. Battery Life**: TIME gauges typically feature long battery life, allowing for extended use in the field without the need for frequent recharging or battery replacement.

Advantages of TIME Ultrasonic Thickness Gauges

1. Non-Destructive Testing**: One of the primary advantages of using ultrasonic thickness gauges is that they allow for non-destructive testing. This means that materials can be evaluated without causing any damage, preserving their integrity and functionality.

2. Cost-Effective**: By helping to assess material conditions accurately, TIME ultrasonic thickness gauges can contribute to cost savings by preventing premature failures and reducing the need for replacement parts.

3. Improved Safety**: Regular thickness measurements can identify potential weaknesses in structures and equipment, leading to proactive maintenance and enhanced safety in workplaces. This is particularly important in industries such as aerospace, oil and gas, and construction.

4. Enhanced Efficiency**: The speed and accuracy of TIME ultrasonic thickness gauges facilitate quick assessments, enabling faster decision-making and reducing downtime during inspections.

5. Versatility Across Industries**: With their ability to measure various materials and thicknesses, TIME ultrasonic thickness gauges are applicable in numerous fields, including automotive, aerospace, manufacturing, and energy sectors.

6. Comprehensive Support**: TIME offers extensive customer support and training resources, ensuring users can maximize the potential of their ultrasonic thickness gauges.

TIME ultrasonic thickness gauges combine advanced technology with user-friendly features to deliver accurate and reliable measurements across various applications. Their non-destructive testing capabilities, durability, and versatility make them invaluable tools for professionals in numerous industries. By investing in a TIME ultrasonic thickness gauge, users can enhance safety, improve efficiency, and ensure the integrity of their materials and structures.