Fiber Reinforced Polymer (FRP) composites have gained significant popularity in various industries due to their exceptional strength-to-weight ratio, corrosion resistance, and versatility.

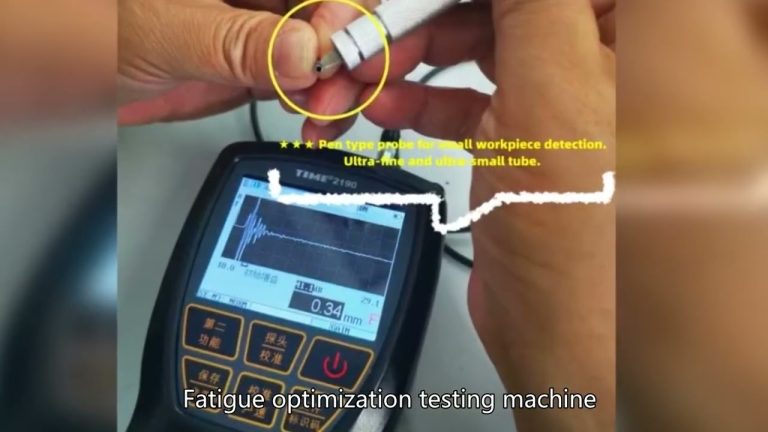

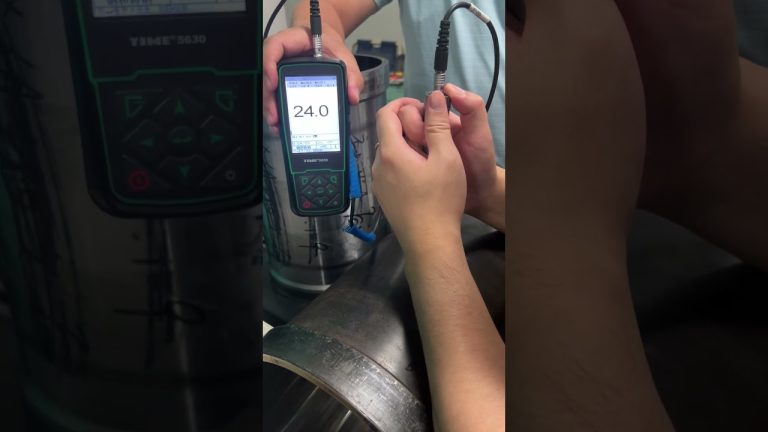

Accurate measurement of the thickness of FRP materials is crucial for quality control, structural integrity assessments, and ensuring compliance with industry standards. One of the most effective tools for this purpose is the Ultrasonic Thickness Gauge (UTG).

Principles of Ultrasonic Thickness Gauging

An Ultrasonic Thickness Gauge operates on the principle of ultrasonic sound waves. The device emits high-frequency sound pulses that travel through the material being tested. When these sound waves encounter a boundary between different materials, they reflect back to the gauge. The time taken for the sound waves to return is measured and used to calculate the thickness of the material based on the speed of sound in that specific medium.

For FRP, the speed of sound can vary depending on the fiber and resin composition, making it essential to calibrate the gauge for accurate measurements. Most ultrasonic thickness gauges come with calibration features that allow users to set the sound velocity for different materials.

Advantages of Using Ultrasonic Thickness Gauges for FRP

- Non-Destructive Testing (NDT): One of the primary benefits of using an ultrasonic thickness gauge is that it does not damage the material being tested. This is particularly important for FRP, where structural integrity is paramount.

- High Accuracy and Precision: UTGs provide precise measurements, often within ±0.1 mm, making them suitable for applications where exact thickness is critical.

- Quick Measurement: The measurement process is rapid, allowing for efficient inspections, especially in industrial settings where time is of the essence.

- Versatility: Ultrasonic thickness gauges can be used on a variety of materials, not just FRP. This makes them a valuable tool for multi-material inspections.

- Portability: Most ultrasonic thickness gauges are lightweight and portable, making them easy to use in various environments, from manufacturing facilities to field inspections.

Limitations of Ultrasonic Thickness Gauges

While ultrasonic thickness gauges are highly effective, there are some limitations to consider:

- Surface Preparation: The surface of the FRP must be clean and smooth for accurate measurements. Any surface irregularities, such as paint or coatings, can affect the readings.

- Material Variability: Different FRP compositions may require specific calibration settings due to variations in sound velocity. Users must be knowledgeable about the material being tested to ensure accurate results.

- Operator Skill: The accuracy of measurements can depend on the operator’s skill and experience. Proper training is essential to maximize the effectiveness of the gauge.

Best Practices for Measuring FRP with Ultrasonic Thickness Gauges

- Calibration: Always calibrate the ultrasonic thickness gauge according to the specific type of FRP being measured. This ensures accuracy in the readings.

- Surface Preparation: Clean the surface of the FRP to remove any dirt, dust, or coatings that may interfere with the ultrasonic signal.

- Multiple Measurements: Take multiple measurements at different points to ensure consistency and identify any potential defects or irregularities in the material.

- Documentation: Keep detailed records of measurements, including location, conditions, and any observations. This documentation is vital for quality control and future reference.

- Regular Maintenance: Ensure the ultrasonic thickness gauge is regularly maintained and calibrated according to the manufacturer’s recommendations to ensure reliable performance.

The ultrasonic thickness gauge is an invaluable tool for measuring the thickness of Fiber Reinforced Polymer materials. Its non-destructive nature, high accuracy, and ease of use make it ideal for various applications in industries such as aerospace, automotive, and construction. By understanding the principles, advantages, and limitations of this technology, professionals can effectively utilize ultrasonic thickness gauges to ensure the quality and integrity of FRP materials. Proper training and adherence to best practices further enhance the reliability of measurements, making it an essential component of modern material testing and inspection processes.