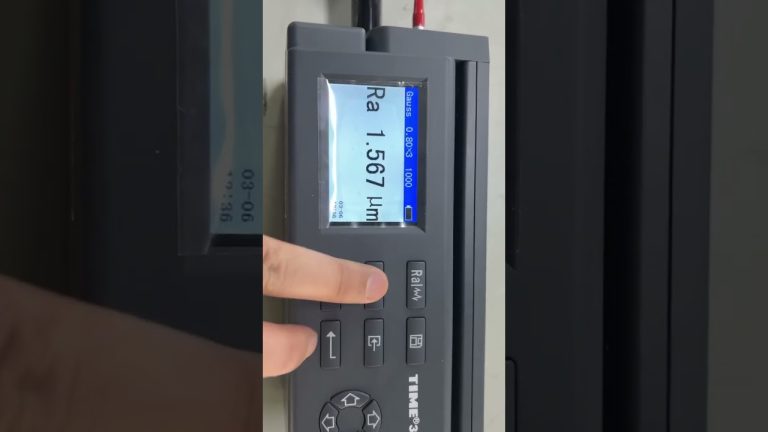

The following aspects should be paid attention to in the daily maintenance of TIME3200 roughness meter:

- After starting the machine every day, use alcohol (absolute ethanol, 99.97%) to clean the marble workbench and marble parts of the columns. Note: Do not use alcohol to wipe the drive box casing, because part of the surface of the casing is spray-painted, which is prone to chemical reactions. Wiping with alcohol can easily affect the appearance.

- Pay attention to the rust prevention of the T-shaped groove of the marble workbench, the screw rod of the column and the column guide rail (the metal part behind the column). Apply anti-rust oil regularly, especially during long holidays.

- When not in use, the TIME3200 roughness meter probe should be removed and placed in a special probe box.

- It is necessary to regularly check the voltage of the power supply of the TIME3200 roughness meter. Please ask user equipment maintenance professionals to cooperate. The specific method is: check whether the voltage value is between 110~~240Vac? Are voltage fluctuations within the allowable range? Are the phase sequence and voltage of L-live wire, N-neutral wire, E-connection wire correct?

- Is there a UPS uninterruptible power supply protection device for external power supply? (Must be installed), in order to prevent the peak voltage caused by the power supply and sudden power outage from damaging the circuit board, computer and electronic components in the control box.

- Are the ambient temperature and humidity of the TIME3200 roughness meter within the allowable range? Operating environment temperature range: 15~30 degrees Celsius, temperature gradient change allowed range: less than 2 degrees Celsius (general environmental requirements, such as processing sites); operating environment temperature range: 18~22 degrees Celsius, temperature gradient change allowed range: less than 2 degrees Celsius (Standard measurement room); humidity requirements: between 45% and 75%.