The Leeb hardness tester is a measuring and testing instrument that plays an important role in ensuring product quality and conducting failure analysis. Therefore, choosing a good Leeb hardness tester is a key issue for users.

Choose imported or domestic Leeb hardness tester?

The Swiss PROCEQ company invented the Leeb hardness tester in 1977. The Leeb hardness tester produced by this company is world-class. Currently, many countries in the world adopt the company’s technical standards as their country’s measurement standards. China’s national measurement standards It is also formulated with reference to the technical standards of PROCEQ Company. The main feature of the Leeb hardness tester produced by the Swiss PROCEQ company is that one host can be configured with seven different types of impact devices. The performance of imported Leeb hardness testers is impeccable, but the price of imported Leeb hardness testers is relatively expensive. It costs about RMB 80,000 to purchase an imported D-type standard configuration Leeb hardness tester, and it is inconvenient to repair if there is a problem. . Domestic Leeb hardness testers are characterized by low prices. It costs about more than 10,000 yuan to purchase a domestic D-type standard configuration Leeb hardness tester. However, domestic Leeb hardness testers have advantages and disadvantages, so you must choose carefully when purchasing.

- How to identify the advantages and disadvantages of Leeb hardness tester?

The real Leeb hardness tester is in line with national standards and international standards and has interchangeability. Although the relevant Chinese departments have formulated national standards for Leeb hardness testers, some manufacturers do not have the technical strength to produce Leeb hardness testers that meet the standard, so they use modified methods to produce Leeb hardness testers. Although their products are also called Leeb hardness tester, but it is far from the real Leeb hardness tester. The original hardness tester with inaccurate measurement value can also meet the accurate requirements for testing hardness test blocks after correction. Therefore, users need to pay attention to choosing a good Leeb hardness tester. The following characteristics of a true Leeb hardness tester: The impact device is interchangeable. One host of the Leeb hardness tester can be configured with seven different types of impact devices at the same time; several impact devices of the same type can be configured on one host.The punch of the striking device is replaceable. The punch of the Leeb hardness tester impact device is replaceable. Punch heads of the same type of impact device can be replaced with each other without affecting the measured value. The Leeb hardness tester is not adjustable. The Leeb hardness tester is not adjustable after leaving the factory. Due to the wear of the ball head, the measurement value is not accurate, so the ball head should be replaced. The measurement error of Leeb hardness tester meets the standard requirements in the full range of hardness. The measurement error of Leeb hardness tester meets the error requirements specified in the standard in the entire range of hardness from low to high. - How to choose the right Leeb hardness tester for yourself

Understand the specifications of the workpiece you need to test, as well as the size, thickness, surface roughness and other physical properties of the workpiece.

The material of the workpiece will also have different effects on the test results, such as aluminum, copper, tool steel and other special materials. Different materials have different rebound modulus. The choice of impulse device is extremely important for the test results.

The purpose of purchasing a Leeb hardness tester is the hardness system that needs to be tested, HL, HB, HRC, HRB, HV, HS. If you meet the above conditions, you can purchase a Leeb hardness tester that can improve your work efficiency. - Calibration of Leeb Hardness Tester

Leeb hardness tester has been widely used in working fields around the world due to its characteristics of easy portability, simple operation, rapid detection and accurate measurement. Due to people’s habits and the hardness measurement standards that have been used for many years, hardness testing methods such as Brinell, Rockwell, Vickers and Shore are still commonly used in actual hardness testing. The Leeb hardness test method only appeared in the past 20 years. It will take some time to completely directly use the Leeb hardness test method for hardness testing. At present, in order to take into account the practicality of Leeb hardness tester and the requirements of traditional hardness measurement standards and meet the needs of hardness testing work, people often convert Leeb hardness values into Brinell, Shore, Rockwell and Vickers hardness values. Whether the Leeb hardness value can be directly converted into other hardness values is related to the impact device used and the hardness material being measured. It often requires a lot of work to establish the conversion relationship between different hardness values. - Standards for Leeb Hardness Tester

Leeb hardness testers have been widely used in metal hardness testing due to their characteristics of easy portability, simple operation, rapid detection and accurate measurement values. Relevant national departments have also promulgated a series of standards for Leeb hardness testers. The following are Let’s give a brief introduction respectively. 1. “Technical Conditions for Leeb Hardness Tester” ZBN71010-90 This standard belongs to the industry standard. It stipulates the technical conditions, test (inspection) methods, inspection rules, completeness and marking, packaging, random documents, etc. of the Leeb hardness tester. standard regulation:

The hardness tester should work normally under the following conditions:

Ambient temperature 0~40℃, relative humidity not more than 90%

No vibration, no strong magnetic field, and no corrosive media in the surrounding environment

The hardness of the tungsten carbide ball on the punch should not be less than 1500HV

error:

The relative error of the indication value does not exceed ±0.8%

The relative error of the repeatability of the indication value should not be greater than 1%

The conversion error between Leeb hardness and Brinell, Rockwell and Vickers hardness is shown in the table below (E=210000N/mm2)

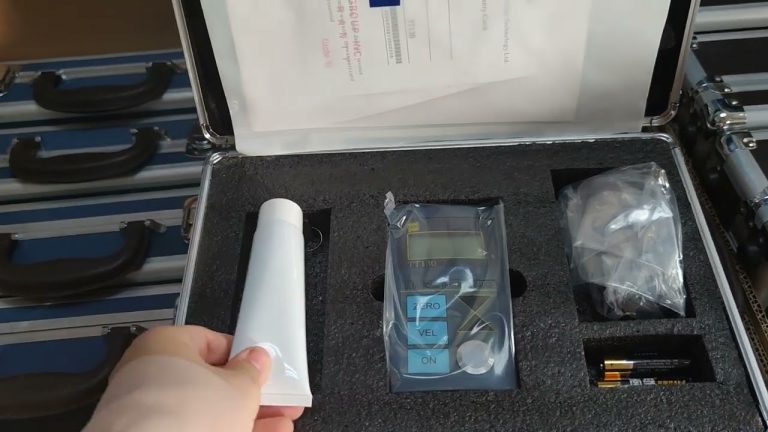

Hardness testers supplied in complete sets should include:

impact device

display device

Ф90×55 is equivalent to a hardness block with a Leeb value of 800±50HL - “Leeb Hardness Tester” JJG747-1999

This standard belongs to the national metrological verification regulations. The regulations outline the testing principles of the Leeb hardness tester, the technical parameters of the impact device, the technical conditions, verification conditions and hardness conversion comparison values of the Leeb hardness tester. The main features of the regulations are: the main technical parameters of various types of impact devices are given. Specifies the technical requirements for standard Leeb hardness blocks. The conversion values of Vickers hardness and Leeb hardness on standard test blocks are given. The conversion values of Brinell hardness and Leeb hardness on the standard test block are given. 3. “Metal Leeb Hardness Test Method” GB/T17394-1998

This standard is the latest national standard. The standard stipulates the test principles, symbols, specimens, test instruments, tests, test result processing and test reports for metal Leeb hardness tests. The main features of the standard are: It stipulates the main technical indicators of the sample, including: surface roughness, weight, minimum thickness, minimum surface hardened layer depth and minimum radius of curvature. Describes the test method for Leeb hardness testing of specimens. Conversion tables between Leeb hardness and other hardnesses for various materials are given. The materials include: carbon steel, cast steel, cast iron, low alloy steel, cast aluminum, copper-zinc alloy, copper-tin alloy, and pure copper. 4. “Conversion Value of Hardness and Strength of Ferrous Metals” GB/T1172-1999 This standard is a national standard. The standard lists the conversion values of ferrous metal hardness and strength. The main steel systems included are: stainless steel and carbon steel, chromium steel, chromium vanadium steel, chromium nickel steel, chromium molybdenum steel, chromium nickel molybdenum steel, chromium manganese silicon steel, Ultra high strength steel.