BEIJING TIME VISION AI INSTRUMENT LTD.

https://timetech-ndt.com/

Email: timehardnesstester@gmail.com

WhatsApp: 008615201625204

——————————————————————————————————–

Hardness tester is a special equipment used to measure the hardness of hull surface. Compared with mechanical hardness testing equipment, the product is easier to carry and measurement is more convenient. At the same time, it can measure the hardness of various materials. High quality NDT insteuments manufacturer, Leeb hardness tester, roughness tester.

The product can wirelessly transmit data to the background for real-time data analysis. The new generation of digital hardness tester eliminates the boring procedures of manual reading of mechanical hardness tester in the past, and realizes the real sense of intelligence and portability.

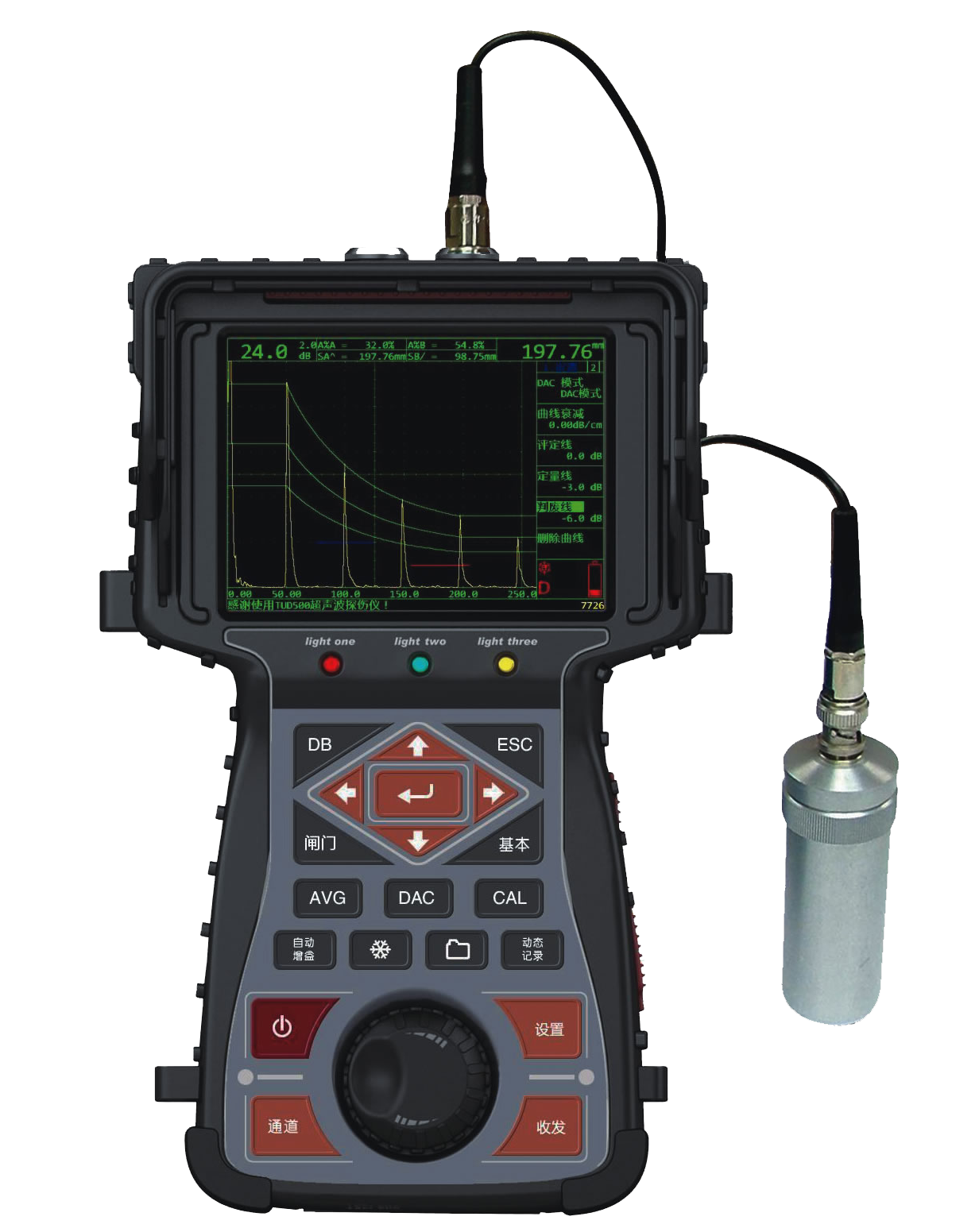

1. Rich experience and reputation: Good instrument manufacturers usually have rich industry experience and a good reputation. They have a long and successful experience in designing, producing and supplying instruments and are recognized and respected by the industry and customers. Hardness tester, roughness tester, thickness gauge, vibration tester, ultrasonic flaw detector. High quality NDT insteuments manufacturer, Leeb hardness tester, roughness tester.

2. Innovation and design capabilities: Good instrument manufacturers focus on innovation and design, and can launch instruments with unique style and fashion. They pay attention to market trends and consumer needs, and continuously develop and improve products to meet different measurement needs. Hardness tester, roughness tester, thickness gauge, vibration tester, ultrasonic flaw detector.

3. High-quality products: Good instrument manufacturers focus on the quality and performance of their products. They use high-quality materials and advanced production processes to ensure the durability and reliability of their products. They conduct strict quality control and testing to provide high-quality instrument products. Hardness tester, roughness tester, thickness gauge, vibration tester, ultrasonic flaw detector.

4. Customer service and after-sales support: Good instrument manufacturers value customer service and after-sales support. They actively communicate with customers, understand their needs, and provide professional technical support and solutions. They respond promptly to customer questions and needs and provide after-sales service to ensure customer satisfaction and long-term relationships. Hardness tester, roughness tester, thickness gauge, vibration tester, ultrasonic flaw detector.

5. Reliable supply chain and delivery capabilities: Good instrument manufacturers have stable and reliable supply chains and efficient delivery capabilities. They are able to promptly supply the required products and deliver them on time, ensuring the smooth progress of customer projects. Hardness tester, roughness tester, thickness gauge, vibration tester, ultrasonic flaw detector.

6. Environmental protection and sustainability: Good instrument manufacturers pay attention to environmental protection and sustainable development. They use energy-saving and environmentally friendly production processes and materials, are committed to reducing environmental impact, and provide products that meet environmental standards. Hardness tester, roughness tester, thickness gauge, vibration tester, ultrasonic flaw detector.