BEIJING TIME VISION AI INSTRUMENT LTD.

https://timetech-ndt.com/

Email: timehardnesstester@gmail.com

WhatsApp: 008615201625204

——————————————————————————————————-

TIME5630 UCI hardness tester, Ultrasonic Hardness Tester factory, thin material hardness measurement.

TIME5630 ultrasonic hardness tester can nondestructively measure the metals and alloys with a minimum thickness of 3 mm.

It can measure strip/plate workpiece, mold hardened layer, blade hardened layer, tooth surface hardened layer, flange edge, wheel, turbine rotor, thin plate, shaft and pipe, container, knife edge, welding part, etc.

● Nondestructive hardness tester for testing hardened layer and thin workpieces

● 3.5-inch color LCD screen

● It indicates the battery status and alarms in low battery

● Conversion of common hardness sales (HV, HB, HRC, HRB)

● Hardness value calibration and delete calibration

● Select the tested material, mainly steel and cast steel. After calibration with the standard test block, it can measure alloy tool steel, special cast iron and non-ferrous metals

● Large memory: built-in 8G SD card.

● Free measurement in all directions, no compensation is needed.

● It can display the maximum value, minimum value, average value, standard deviation, measurement times, previous measurement values, etc.

● Upper/lower limits setting and alarm when out of the limits

● Rechargeable lithium ion battery, continuous working time is more than 30 hours

● Portable stand to enhance the measurement accuracy

Standard Delivery

● Main unit

● 10N manual probe

● Standard test block

● V-shape base

● Probe cable

● Charger

● TIME certificate

● Warranty card

● Instruction manual

Optional Accessory

● 20N manual probe

● 50N manual probe

● TIMEA531 operation stand

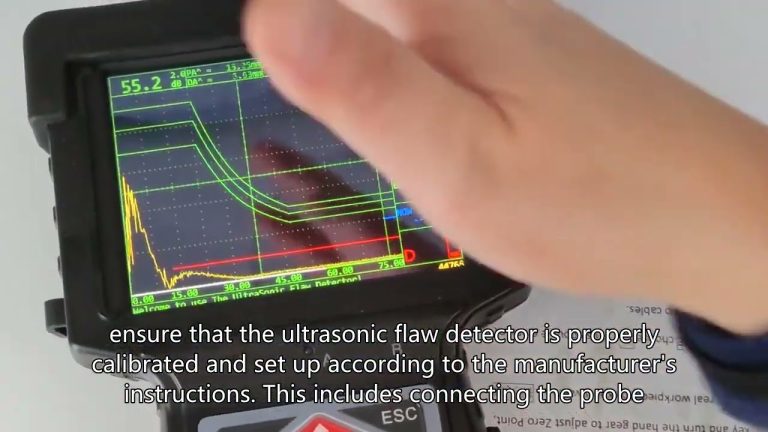

The ultrasonic hardness tester consists of a handheld PDA and a CUI measurement probe. The two are connected by a cable. The diamond indenter at the front of the hardness tester is in contact with the test piece. Under uniform contact pressure, the resonant frequency of the probe changes with the hardness. Change, by measuring the change in frequency, the purpose of measuring hardness is achieved. Home / / Product / Portbale Hardness Tester / Ultrasonic Hardness Tester TIME5630 https://timetech-ndt.com/product/ultrasonic-hardness-tester-time5630/

A hardness tester that uses the characteristic that the resonant frequency of an ultrasonic sensor rod with an indenter is in contact with the surface of the test piece changes with the hardness of the test piece to measure the hardness value.

There are many methods that can be used for hardness testing, such as Brinell, Rockwell, Vickers, Leeb, ultrasonic, etc. Among them, Brinell and Rockwell hardness cause greater damage to the surface of the object to be tested, while Vickers has a higher cost, and neither can test large workpieces; Leeb hardness tester is an indirect measurement of hardness, and the test deviations of Brinell, Rockwell, and Vickers are large. . With the technological development of microprocessors, ultrasonic non-destructive testing methods have gained industry recognition. Ultrasonic thickness gauges and flaw detectors have been widely used, and ultrasonic hardness meters have also become popular abroad. Ultrasonic Hardness Tester TIME5630 https://timetech-ndt.com/product/ultrasonic-hardness-tester-time5630/

Principle of ultrasonic hardness tester

The diamond indenter of the hardness tester is brought into contact with the test piece. Under uniform contact pressure, the resonant frequency of the probe changes with the hardness. The purpose of measuring the hardness is achieved by measuring the change in frequency. This method will extremely damage the test piece. It is small and has great advantages compared with other methods mentioned above.

Application occasions

The workpiece parts that can be measured by the ultrasonic hardness tester include flange edges and gear root stampings; tool dies and thin plates; measurement of surface-hardened teeth and gears; hardness measurement of taper parts; measurement of shafts and thin-walled pipes and containers; wheels, Hardness measurement of turbine rotor; hardness measurement of drill edge; welding parts;

TIME630 portable ultrasonic hardness tester is an outstanding representative in the field of hardness testing. It is small in size and easy to operate. It adopts the innovative UCI method for hardness measurement. Its flexible and changeable material moving hardness testing and multi-functional hardness measurement meet different needs, and automatic measurement and big data storage improve efficiency. Widely applicable to various materials and scenarios to ensure the accuracy and reliability of test results.