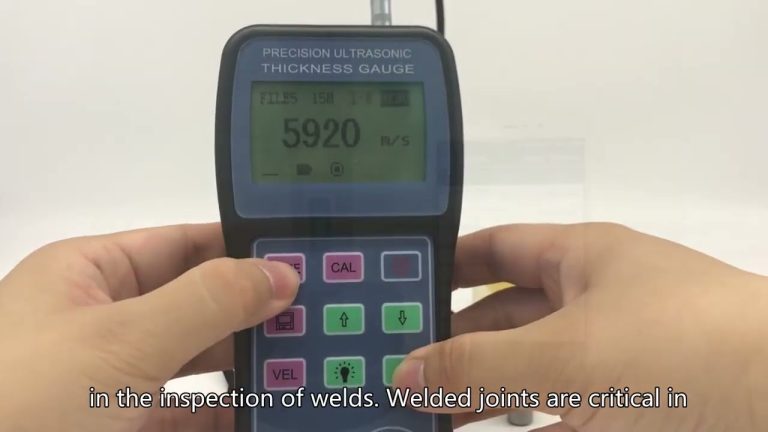

TIME®2190 is the latest high-end ultrasonic thickness gauge developed by TIME Group Inc. It adopts pulse reflection principle, that is, the transducer sends ultrasonic pulses to travel through the test object and receives the reflection pulse from the backwall of the object.

TIME2190 can nondestructively monitor the thickness of almost any material like metals, plastics, composites, fiberglass, ceramics, and glass with A scan/B scan. It is used to test the wall thickness and corrosion of various kinds of plates, pipes, boilers, vessels across industries like metallurgy, shipbuilding, machinery, chemical, aerospace, power, automotive, oil and gas, manufacturing and others.

Features

» A-scan waveform can be displayed for echo analysis and measurement of complex workpiece;

» Compatible with many types of transducers, single and dual element transducers are suitable;

» With a variety of measurement methods, users can set blanks to shield aftershocks or clutter;

» Echo-echo measures the true metal thickness with ignoring the thickness of coating layer.

Thru-coat technology measures metal and nonmetallic coating thickness.

» Signal auto-amplification function (centered display of the detected echo);

» The resolution is 0.001, 0.01, 0.1 mm optional in any mode (or 0.0001, 0.001, 0.01 inch optional)

» Gain adjustment range 0-99dB;

» Adjustable voltage variable pulse width square wave pulse generator;

» Single value B-scan display function;

» Users can turn on fast measurement mode up to 20 times per second;

» Alarm function, user can set the upper and lower limits of the alarm;

» Differential, maximum and minimum display mode;

» Internal data storage, data can be output to a removable MicroSD memory card. Can store up to

500,000 measured values and waveforms;