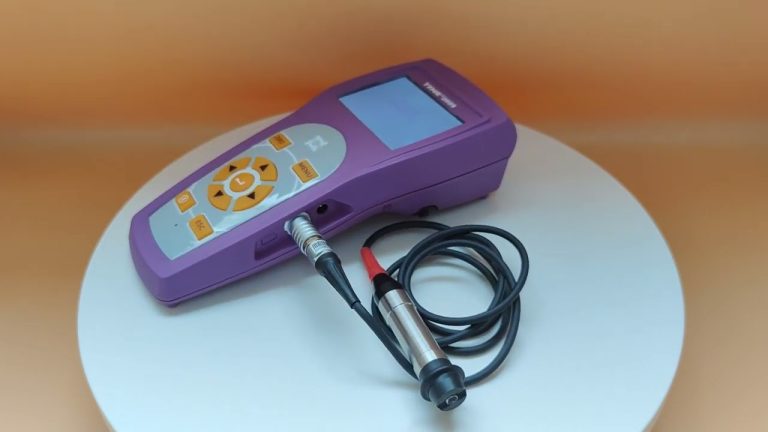

In the realm of manufacturing and quality control, surface roughness plays a critical role in determining the functionality and aesthetic appeal of a product. A roughness tester, also known as a surface roughness measuring instrument, is essential for assessing the micro-geometric features of surfaces.

Key Parameters of Roughness Testers

1. Roughness Parameters

Roughness testers utilize various parameters to quantify surface roughness. The most common parameters include:

– Ra (Arithmetic Average Roughness): This is the average of absolute values of surface height deviations measured from the mean line over a specified length. It is one of the most widely used roughness parameters.

– Rz (Average Maximum Height of the Profile): This parameter measures the vertical distance between the highest peak and the lowest valley in a given sampling length. It provides insight into the overall texture of the surface.

– Rq (Root Mean Square Roughness): This is the square root of the average of the squared deviations from the mean line. Rq is sensitive to larger surface variations and is useful for identifying significant surface features.

– Rt (Total Height of the Profile): This parameter represents the total height difference between the highest peak and the lowest valley over the evaluation length. It gives a clear understanding of the surface’s extremes.

2. Measurement Length

The measurement length, or sampling length, is critical in determining the roughness of a surface. It influences the calculated roughness parameters and is typically defined based on the surface characteristics being measured. Common lengths range from 0.25 mm to 10 mm, depending on the application. A longer measurement length may provide a more representative average, while a shorter length can reveal localized roughness features.

3. Cut-off Length

The cut-off length is the length over which the roughness is evaluated. It is essential for filtering out long-wavelength variations that could skew the roughness measurements. Standard cut-off lengths include 0.08 mm, 0.25 mm, and 0.8 mm, and the choice depends on the specific requirements of the surface being tested.

4. Stylus Tip Radius

The stylus tip radius affects the measurement accuracy and resolution of the roughness tester. A smaller stylus tip radius can detect finer surface features, while a larger radius may average out these details. Therefore, selecting the appropriate stylus tip is crucial for achieving accurate measurements.

5. Traverse Speed

Traverse speed refers to the rate at which the stylus moves across the surface. This parameter can influence the measurement results, as a faster traverse speed may lead to inaccuracies due to insufficient data acquisition. Manufacturers typically specify optimal traverse speeds to ensure reliable results.

6. Calibration and Standardization

Regular calibration of roughness testers is essential to maintain measurement accuracy. Calibration involves comparing the tester’s readings against known standards to ensure that it produces reliable results. Following industry standards, such as ISO or ASME, is crucial for consistency and comparability of roughness measurements.

Understanding the parameters of roughness testers is vital for achieving accurate surface roughness measurements. By carefully selecting and managing parameters such as roughness types, measurement lengths, cut-off lengths, stylus tip radius, and traverse speed, manufacturers can ensure high-quality production standards. Proper calibration and adherence to industry standards further enhance the reliability of roughness testing, ultimately leading to improved product performance and customer satisfaction.