Lightning rods play a critical role in protecting structures from lightning strikes by providing a safe path for electrical discharges to follow. The effectiveness of a lightning rod is not solely dependent on its material and design but also on its dimensions, especially thickness.

Accurate thickness measurement of lightning rods is essential to ensure their reliability and performance. This article explores various methods and techniques for measuring the thickness of lightning rods, emphasizing the importance of precision in this process.

Importance of Thickness Measurement

The thickness of a lightning rod influences its ability to conduct electricity and withstand the intense heat generated by a lightning strike. A rod that is too thin may not adequately handle the electrical load, leading to potential failure during a storm. Conversely, an excessively thick rod may be unnecessarily heavy and costly. Therefore, precise thickness measurement is essential for manufacturers, engineers, and safety inspectors to ensure that lightning rods meet industry standards and regulations.

Methods of Thickness Measurement

Several techniques can be employed to measure the thickness of lightning rods, each with its advantages and limitations:

1. Caliper Measurement

One of the simplest and most direct methods for measuring the thickness of a lightning rod is using calipers. This tool allows for precise measurements by placing the caliper jaws around the rod and reading the measurement on the scale. While effective for rods with uniform thickness, calipers may not be suitable for rods with irregular shapes or surfaces.

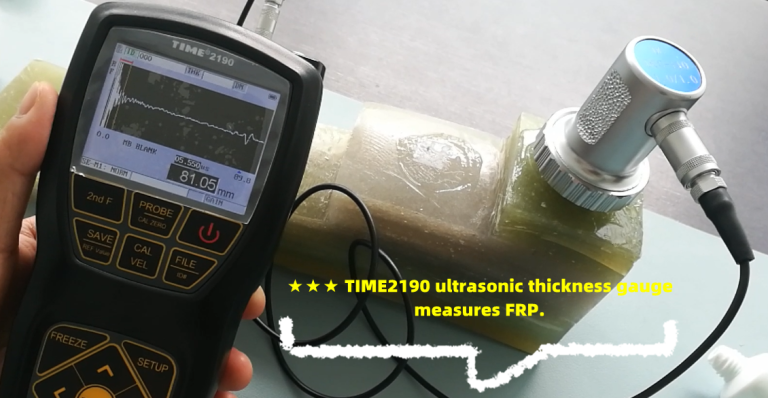

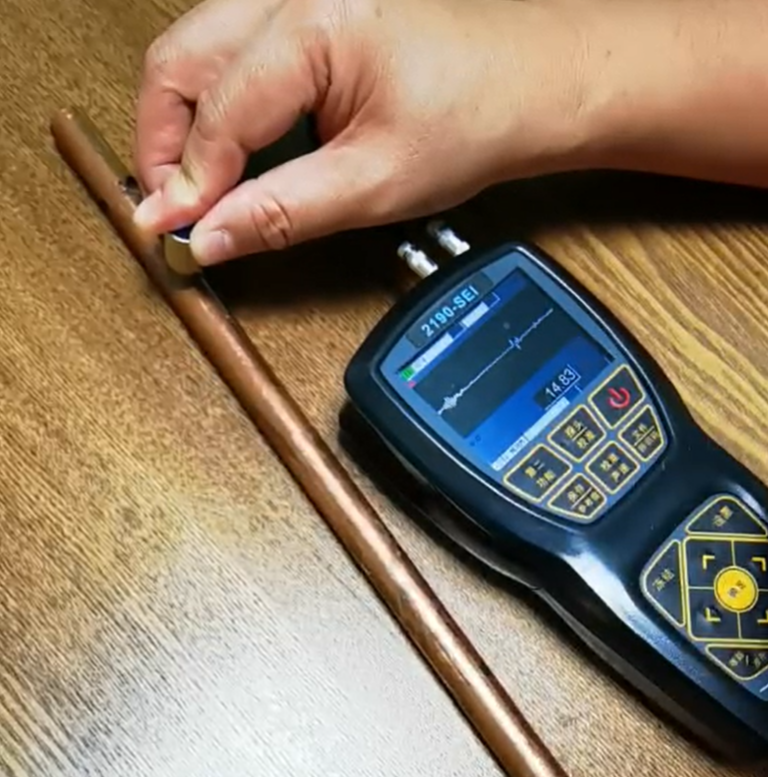

2.Ultrasonic Thickness Gauging

Ultrasonic thickness gauging is a non-destructive testing method that uses high-frequency sound waves to measure material thickness. An ultrasonic transducer emits sound waves that travel through the rod and reflect back when they hit the opposite surface. The time taken for the echo to return is used to calculate the thickness. This method is particularly useful for thicker rods and can provide accurate results without damaging the material.

3.Magnetic Induction Measurement

Magnetic induction is another non-destructive technique that can be employed to measure the thickness of conductive materials, including metals used in lightning rods. This method involves placing a probe on the rod’s surface, which generates a magnetic field. The response of the material to the magnetic field can be analyzed to determine its thickness. This method is effective for measuring the thickness of coatings or layers on the rod as well.

4. X-ray Measurement

X-ray thickness measurement is a highly accurate method that uses X-ray technology to assess the thickness of materials. This technique is particularly useful for complex geometries and can provide detailed information about both thickness and material composition. However, it requires specialized equipment and safety precautions due to the use of radiation.

Accurate thickness measurement of lightning rods is crucial for ensuring their performance and reliability in protecting structures from lightning strikes. Various methods, including caliper measurement, ultrasonic gauging, magnetic induction, and X-ray measurement, each offer unique advantages depending on the specific requirements of the measurement task.

By employing the appropriate technique, manufacturers and inspectors can ensure that lightning rods meet necessary safety standards and effectively safeguard against electrical hazards. As technology continues to evolve, the methods for measuring thickness will likely become even more precise and efficient, further enhancing the safety and reliability of lightning protection systems.