With the continuous improvement of people’s living standards and the increasing requirements for material and quality of life, color management has been put on the agenda. The application of colorimeter is undoubtedly indispensable. All aspects of our lives depend on color, and our clothes are Colorful, our daily necessities, pots and pans are colorful, and our reading materials, magazines, and papers are colorful. Everything is inseparable from color.

In recent years, the cosmetics industry has made a wave in the female circle of friends, but it is different. Cosmetics also have different color differences, including color differences in packaging, color differences in foundations, cosmetics, etc.

The colorimeter plays a decisive role in all aspects.

For a high-end cosmetic, both its packaging and function must be as perfect as possible, because exquisite pig girls are always the most serious about cosmetics, and they cannot be allowed to have a doubt or an excuse to reject the product. Perfect packaging is inseparable from accurate color matching. Too much color difference always gives people a feeling of inferior quality. Therefore, merchants are making every effort to minimize the impact of color difference on packaging. Senquan Technology’s precision colorimeter, spectrophotometer, etc. can meet these simple needs.

Color difference, “Cihai” explains, refers to the difference between two colors, that is, the comprehensive difference of hue, saturation and brightness. In order to achieve customer satisfaction and avoid unnecessary losses caused by color difference, we must widely use colorimeter in daily life to achieve the best color management.

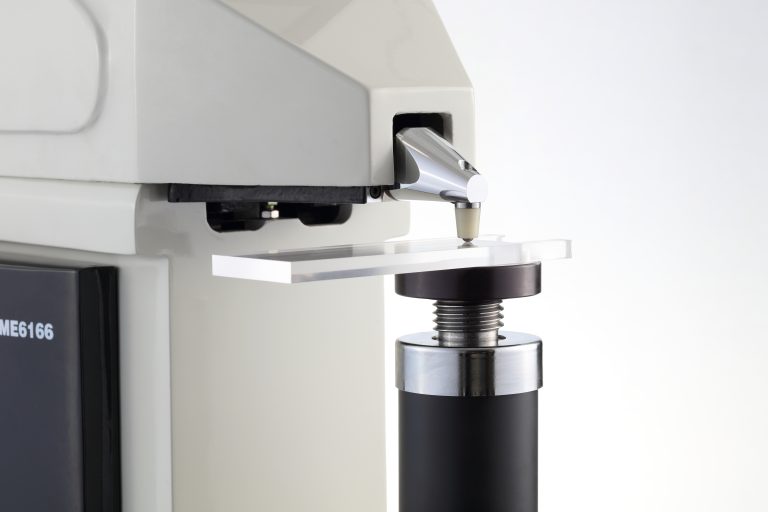

- Measurement of color adjustment with colorimeter:

When a customer gets a sample and needs to reproduce the same color of the sample, he or she needs to confirm the sample repeatedly. Early color management relied on human eyes to compare the difference between the sample and the standard sample, but this difference is not visible to the naked eye. If it is noticeable or seems very inconspicuous, the process is handed over to the workshop for production. This method is too subjective. Not everyone’s views and visual effects are the same, and it is greatly affected by external factors. Therefore, people use colorimeter to cooperate with computer system in modern color management. The biggest advantage of using colorimeter to participate in color matching is that the formula can be corrected based on the data provided by the colorimeter, so that the color matching task can be completed faster and more accurately.

- The role of colorimeter in quality control:

After the formula is determined and put into production, due to changes in many factors during production, color deviations may occur in batches of products. In this way, a colorimeter must be frequently used to measure color deviations during production to adjust the production process to achieve consistent product colors. sex.

- In terms of mass communication:

Nowadays, customers generally provide color cards or samples. In this way, when signing a contract with the user, try to keep the actual object as a standard. The colorimeter also has deviations according to the actual environment. The national color benchmarks are all based on standard white boards and color boards. benchmark, rather than instrument-based benchmark.