BEIJING TIME VISION AI INSTRUMENT LTD.

https://timetech-ndt.com/

Email: timehardnesstester@gmail.com

WhatsApp: 008615201625204

——————————————–

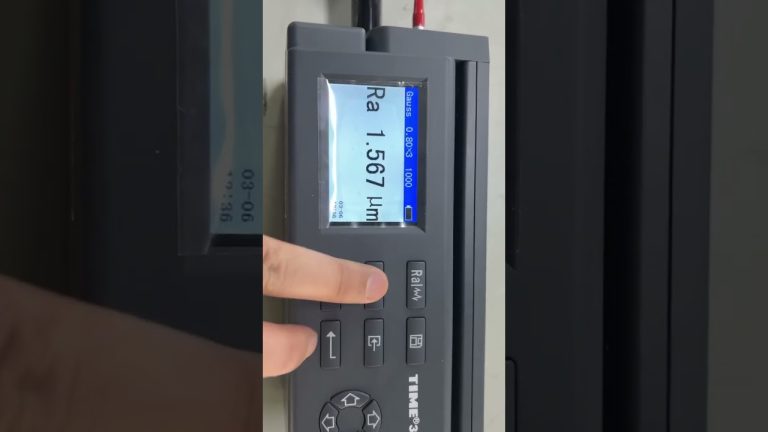

monsanto hardness tester procedure,TIME surface roughness tester sj-201 manual,Ultrasonic thickness gauge calibration ,tubing wall thickness gauge chart,Benchtop hardness tester lowest price manufacturer,hull roughness gauge,thickness gauge procedure,Ultrasonic thickness gauge precision supplier Chinese,nanovea profilometer,hardness test gif.

How to choose the bond surface roughness parameter value Ra?

Answer: The bonding form is a key, and when moving along the hub groove, Ra is 0.2-0.5μm.

The bonding form is a key, and the Ra is 0.2-0.4μm when moving along the axis groove. Ultrasonic Thickness Gauge TIME2190 with A/B scan https://timetech-ndt.com/product/ultrasonic-thickness-gauge-time2190-with-a-b-scan/

The bonding form is a bond, and the fixed position, Ra is 1.6μm.

The combination form is a shaft groove. Where it moves along the hub groove, Ra is 1.6μm.

The combination form is an axis groove, and when moving along the axis groove, Ra is 0.4-0.8μm.

The combination form is a shaft groove, and the fixed position, Ra is 1.6μm.

The combination form is a hub groove, and when moving along the hub groove, Ra is 0.4-0.8μm.

The combination form is a hub groove. Where it moves along the shaft groove, Ra is 1.0μm.

The combination form is hub groove, and the fixed position, Ra is 1.6-3.2μm.

Note: The non-working surface Ra is 6.3μm. Digital Shore A Hardness Tester TIME5430 https://timetech-ndt.com/product/digital-shore-a-hardness-tester-time5430/

65. How to choose the surface roughness parameter value Ra of rectangular spline?

Answer: Internal spline, at the outer diameter, Ra is 6.3μm.

Internal spline, inner diameter, Ra is 0.8μm.

Internal spline, key side, Ra is 3.2μm.

External spline, at the outer diameter, Ra is 3.2μm.

External spline, inner diameter, Ra is 0.8μm.

External spline, key side, Ra is 0.8μm.

66. How to choose the gear surface roughness parameter value Ra?

Answer: When the part is the tooth surface and the accuracy level is level 5, Ra is 0.2-0.4μm. Ultrasonic Thickness Gauge TIME2170 (TT700) https://timetech-ndt.com/product/ultrasonic-thickness-gauge-time2170-tt700/

When the tooth surface accuracy level is level 6, Ra is 0.4μm.

When the tooth surface accuracy level is level 7, Ra is 0.4-0.8μm.

When the tooth surface accuracy level is 8, Ra is 1.6μm.

When the tooth surface accuracy level is level 9, Ra is 3.2μm.

When the tooth surface accuracy level is level 10, Ra is 6.3μm.

When the part is an outer circle and the accuracy level is level 5, Ra is 0.8-1.6μm.

When the part is an outer circle and the accuracy level is level 6, Ra is 1.6-3.2μm.

When the part is an outer circle and the accuracy level is level 7, Ra is 1.6-3.2μm.

When the part is an outer circle and the accuracy level is level 8, Ra is 1.6-3.2μm.

When the part is an outer circle and the accuracy level is level 9, Ra is 3.2-6.3μm.

When the part is an outer circle and the accuracy level is level 10, Ra is 3.2-6.3μm.

When the end face accuracy level is level 5, Ra is 0.4-0.8μm.

When the end face accuracy level is level 6, Ra is 0.4-0.8μm.

When the end face accuracy level is level 7, Ra is 0.8-3.2μm.

When the end face accuracy level is level 8, Ra is 0.8-3.2μm.

When the end face accuracy level is level 9, Ra is 3.2-6.3μm.

When the end face accuracy level is level 10, Ra is 3.2-6.3μm.

How to choose the surface roughness parameter value Ra of worm gear?

Answer: When the worm part is the tooth surface and the accuracy level is level 5, Ra is 0.2μm.

When the worm part is a tooth surface with an accuracy level of 6, Ra is 0.4 μm.

When the worm part is a tooth surface with an accuracy level of 7, Ra is 0.4 μm.

When the worm part is a tooth surface with an accuracy level of 8, Ra is 0.8 μm.

When the worm part is a tooth surface with an accuracy level of 9, Ra is 1.6 μm.

When the worm part is the tooth tip and the accuracy level is level 5, Ra is 0.2μm.

When the worm part is the tooth tip and the accuracy level is level 6, Ra is 0.4μm.

When the worm part is the tooth tip and the accuracy level is level 7, Ra is 0.4μm.

When the worm part is the tooth tip and the accuracy level is level 8, Ra is 0.8μm.

When the worm part is the tooth tip and the accuracy level is level 9, Ra is 1.6 μm.

Note: The worm part is the tooth root, and Ra is 6.3μm.

When the worm gear part is a tooth surface with an accuracy level of 5, Ra is 0.4 μm.

When the tooth surface accuracy level of the worm gear is level 6, Ra is 0.4μm.

When the worm gear part is a tooth surface with an accuracy level of 7, Ra is 0.8 μm.

When the worm gear part is a tooth surface with an accuracy level of 8, Ra is 1.6 μm.

When the worm gear part is a tooth surface with an accuracy level of 9, Ra is 3.2 μm.

Note: The worm gear part is the tooth root, and Ra is 3.2μm.