Refers to the performance of metal magnetic conductivity; in terms of practical significance, such as: Magnetic materials (metal) to create permanent magnets and electrical materials, or magnetic metals can be used to check whether magnetic metals have cracks, etc.

- What is conductivity?

Answer: Refers to the nature of the metal that can transmit current. - What is magnetic?

Answer: Refers to the performance of metal magnetic conductivity; in terms of practical significance, such as: Magnetic materials (metal) to create permanent magnets and electrical materials, or magnetic metals can be used to check whether magnetic metals have cracks, etc. - What is high pressure?

Answer: Those with a ground voltage of the device are called high voltage above 250 volts.

Fifty -three, what is low pressure?

Answer: Those with a ground voltage of the device are called low voltage below 250 volt. - What is a safe voltage?

Answer: When a person touching a charged conductor, the voltage without life is generally used as a safe voltage with a voltage of less than 36 volts.

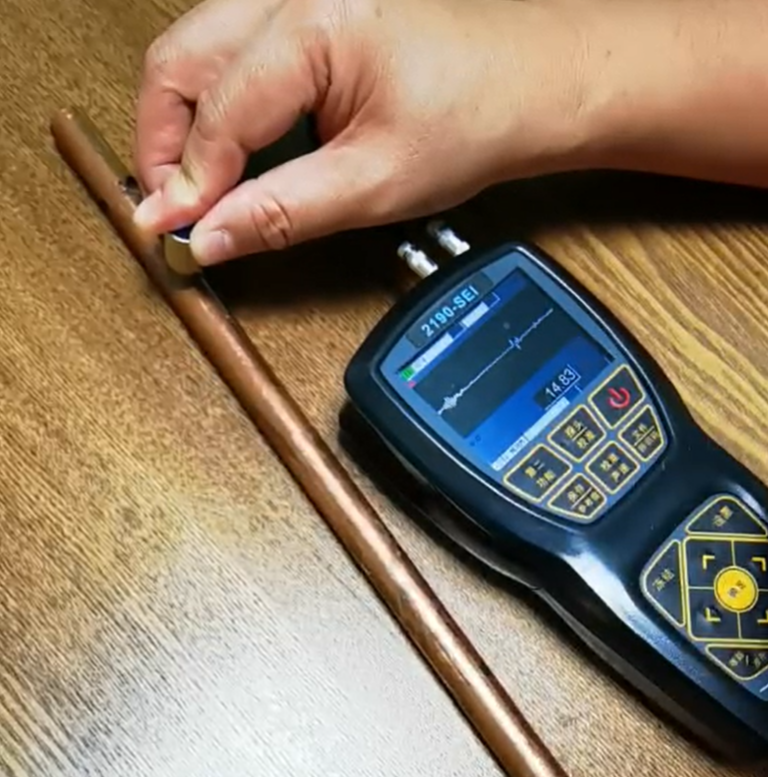

Whenever the workplace is humid or in a metal container, the lighting of electrical appliances in tunnels and ores uses a 12 -volt safety voltage. - What is the role of ultrasonic test blocks?

Answer: The role of ultrasound test block is to check the performance of the instrument and probe, determine the starting sensitivity of the probe, and calibrate the scanning linear. - What is the correct value of the oblique probe refraction angle β?

Answer: The correct value of the refraction angle of the oblique probe is called the K value, which is equal to the horizontal distance and the corresponding depth ratio of the oblique probe λ shooting point to the reflection point. - What should I do if there is a defect that is not allowed in the weld in the welding of the local non -destructive detection?

Answer: It should be replenished in the direction of defects or suspicious parts. After the replenishment, the quality of the weld is still suspected that all the welds should be explored. - How many magnetic marks caused by non -defects?

Answer: 1. Local cold work hardening, the magnetic marks accumulated by the magnetic changes caused by materials; 2. The accumulation of magnetic powder accumulation at the interface of two different materials; 3. The analysis of the tissue of the carbide layer; 5. The magnetization current is too high, the magnetic marks caused by the metal streamline; 6. The spots -like magnetic marks caused by the non -cleaning or oil stain due to the surface of the workpiece.

Fifty -nine, what are the magnetic powder inspection regulations?

Answer: 1. Scope of application of procedures; 2. Magnetization methods (including magnetization specifications, preparation of workpiece surface); 3. Magnetic powder (including the preparation of granularity, color, magnetic suspension and fluorescent magnetic suspension). 4. Test films; 5. Technical operation; 6. Quality assessment and inspection records.