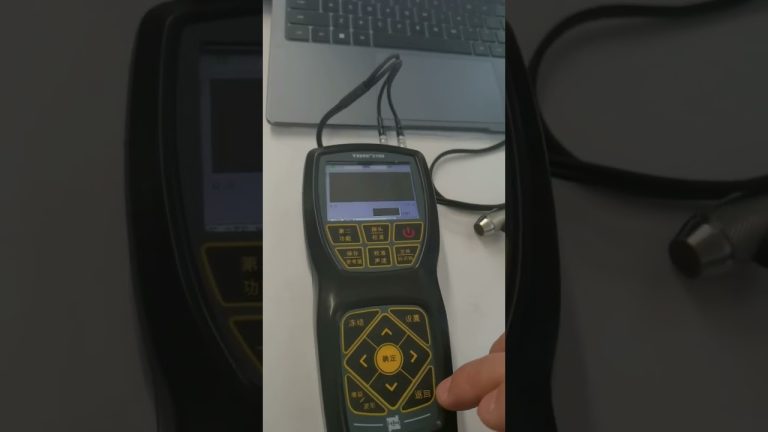

As a portable hardness tester, the ultrasonic hardness tester has its unique advantages: portability, no damage to the workpiece, high accuracy, and simple and convenient operation. Currently, when providing optional accessories for ultrasonic hardness testers from global mainstream brands, there are a variety of different probes to choose from.

The distinction between these different probes is first of all the difference in loading methods, that is, manual loading and electric loading. The other distinction is through different loading forces, that is, loads. Different loads are suitable for different workpieces. At present, there is no national standard for ultrasonic hardness testers, and there are no rigid regulations on what load is suitable for what workpiece, so many users do not understand it.

First of all, the common loads of ultrasonic hardness tester probes are: 3N, 10N, 30N, 49N, 98N. Using different loads may produce different measurement results. Below, we will explain what load probe should be selected when choosing an ultrasonic hardness tester. .

3N load: The loading force of 3N is the smallest of all loads and can be considered a small load probe. Because of its small load, it is more suitable for some relatively thin workpieces, with a minimum thickness of 1.5mm, such as steel plates or hollow thin-walled steel pipes below 5mm; or very thin partial electroplating where the design parameters of the part require 3N load measurement The hardness of the layer, commonly measured on chrome and copper plating on printing cylinders.

10N load: 10N loading force, suitable for most quenched, nitrided, carburized workpieces with good surface roughness (Ra<1.6), such as bearings, crankshafts, supports, molds, etc.; plates or pipe fittings with a thickness greater than 5mm and pressure vessels; or common industrial electroplated chromium (chromium plating thickness greater than 10um) parts, such as chrome-plated rollers, etc.

30N load: 30N loading force. Because of its large load, it is generally used as a manual probe. It is suitable for workpieces that are rough and cannot be surface polished, such as large gear tooth surfaces with rough surfaces.

49N load: 49N loading force, suitable for rough surfaces and unpolished welds.

98N load: rough casting.